Flexcaster stair mould for producing stairs upside down

Moulds for stairs with top and bottom landings, this formwork is suitable for producing stairs upside down (steps facing downwards)

An electric control panel with a remote control operates an electric linear actuator to adjust the distance between the individual steps. In this way, the tread of the steps is adjusted simultaneously. A second electric actuator is also provided to adjust the riser height of the entire staircase at once.

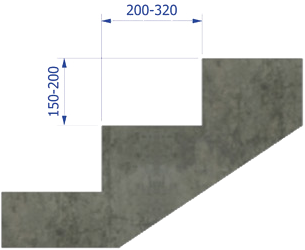

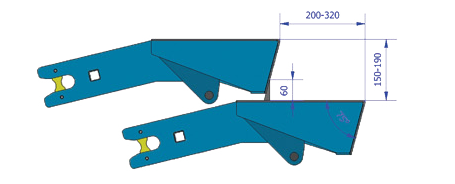

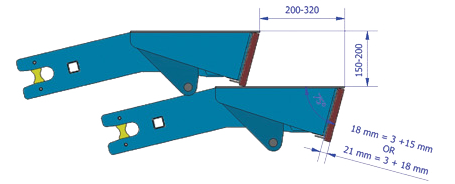

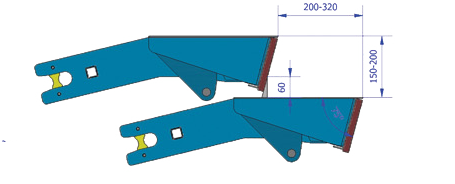

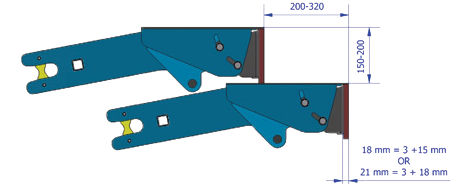

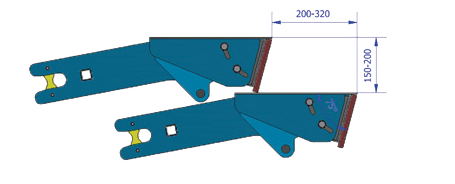

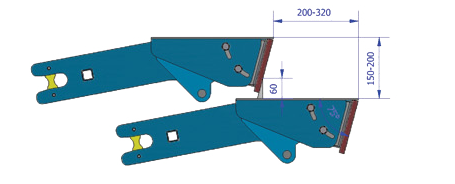

Consequently, both goings and risers can be adjusted and synchronised by 2 motorised movements:

- Goings adjustable between 200mm and 320mm

- Risers adjustable between 150mm and 200mm

Usually, the width of the stair mould is 1,5m but this can be wider, up to 4m. In the wider moulds 2 stairs can be cast next to each other. Customers can choose any number of steps, but the number usually varies between 10 and 24. Long moulds with 20 steps or more can be used to cast 2 flights of stairs with a limited number of steps simultaneously. The stair moulds can be equipped with an electric tilting device to facilitate the installation of the reinforcement, the removal of the concrete stairs and the cleaning of the mould.

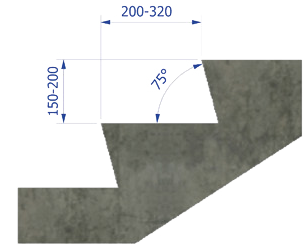

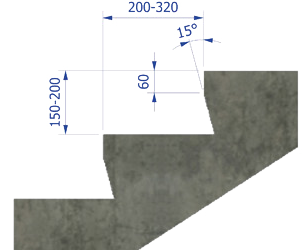

One side of the stair mould is equipped with a height-adjustable side panel. As a result of this height adjustment, the steps can vary in thickness between 120mm and 250mm. For non-tilting wide stair moulds, an extra adjustable side panel on the other side is an appropriate option. The stair mould includes 2 sets of landing equipment (top and bottom). The panel for the bottom landing is constructed as an extended first step element. The angle of the bottom landing panel can be manually controlled with great precision by means of 2 synchronised spindles. The panel for the top landing sits on a carriage and can be inserted at every position after removing a few step.

If the top landing carriage is set up at the rear of the mould, it will be linked to the last axle, thus travelling back and forth when the goings and risers are hydraulically adjusted. The angle of the top landing panel can be manually controlled with great precision by means of 2 synchronised spindles.

PLC-controlled

As an option, the moulds can be PLC-controlled. The operator uses a touch screen to enter the height adjustments of the risers and goings. The PLC then checks all the safety sensors to see if the mould is ready to be set, after which the bearings and all the steps are adjusted according to the operator's instructions. It takes just 3 minutes to complete a full cycle with nothing left to measure before the mould is ready for use. Other advantages of using a PLC are higher safety and quality standards, and maintenance made much more convenient. A "cleaning button" fixes the mould in the open position, making it easier to clean the mould. Several sensors check whether the side wall and pressure beam are completely closed, and a visual check on the screen shows at what angle the upper and lower bearings are set. This makes it easy to check drawings and design data, without the need for additional measuring equipment.

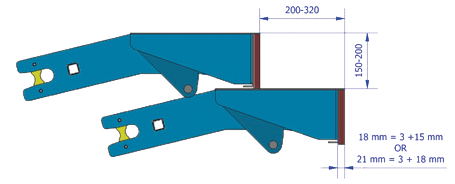

The most common feature of the steps is the one with the articulating front. These fronts are designed with a support plate which falls back 18mm, incorporating timber blocks and magnets. They can be used to fit 18mm plywood strips or 3mm metal plates onto which 15mm plywood strips are screwed. The steps with cut-back and nose can be produced by using triangular magnetic chamfers which can overlap an opening of 40mm.

| The steps can feature several designs | 1. Straight Steps |

2. Steps with cut-back |

3. Steps with cut-back and nose |

|---|---|---|---|

| A. Straight steps with timber front |  |

||

| B. Steps with fixed cut-back, steel front and magnetic chamfer |  |

||

| C. Steps with fixed cut-back, timber front and magnetic chamfer |  |

|

|

| D. Steps with articulating timber front and magnetic chamfer |  |

|

|

Request your quote